-

FIELD OF APPLICATION

- Water treatment plants, downstream of the blowers used to input air into tanks (oxidation, primary treatments, etc.).

- Suitable fluids: air, nitrogen, carbon dioxide.

- Suitable fluids: air, nitrogen, carbon dioxide.

- Non-suitable fluids: flammable, hazardous, or corrosive gases

-

MAIN FEATURES

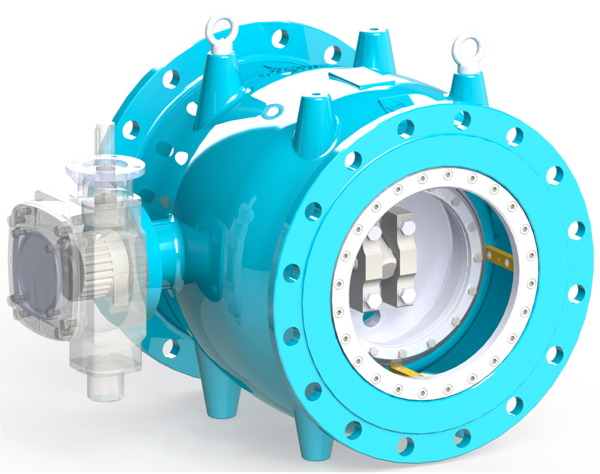

- MOD. F560

FROM DN80 TO DN150 (PN10 | PN16)

- MOD. F500

FROM DN200 TO DN600 (PN10 | PN16)

STANDARD: EN 1074-5

FACE TO FACE: EN 558 Serie 15

FLANGES: EN 1092-2

TEST: EN 12266-1

WORKING TEMPERATURE: Min. +0°C (frost excluded) Max. +100°C

ALLOWED WORKING DIFFERENTIAL PRESSURE: Max 1 bar

INLET PRESSURE: Max. 2 bar

FLOW VELOCITY IN THE PIPELINE (INLET): Max 30 m/s

INTERNAL SURFACE: FBE coating process with epoxy resin powder of blue colour RAL 5015 and thickness of 300µm according to EN 14901 and second layer in epoxy polyester in color blue RAL 5012 with average thickness 50 μm

EXTERNAL SURFACE: FBE coating process with epoxy resin powder of blue colour RAL 5015 and thickness of 300µm according to EN 14901

GEARBOX:

- Self locking worn gear

- Bronze wheel lubracated with Shell Alvania 1029

- Suitable for coupling with actuators through connection top flange according to ISO 5210

- Double sealing

- IP68 enclosure protection according to EN 60529

- Internal/External KS coating of grey colour RAL 7037 and average tickness of 140 μm suitable for highly corrosion environments, classification C5-I according to EN15714-2