Pressure reducing station

with electricity production

Water pipeline networks feature numerous pressure reducing stations that play a crucial role in ensuring that water reaches the end users with controlled flow and pressure. Each Station has a control valve whose function is to reduce pressure by dissipating energy.

With FR Line this dispersion is converted into electricity which can be directly used or fed into the grid. The system’s output is sufficient to repay the investment made in a few years.

The goal set by T.I.S. Research and Development Centre - made up of experts in the design and management of water network services with a particular focus on drinking water, and in the design and construction of various types of valves and hydroelectric power facilities - was to design a pressure reducing Station, capable to generate energy, that would meet all the essential constraints.

for effective management of drinking water services, i.e. that would:

- Guarantee supply continuity, in terms of both pressure and flow rate, as required by the user

- Offer quick and easy installation and start-up, so as not to undermine supply continuity

- Feature a compact design which is compatible with existing site structures

- Use certified materials with specifications that confirm their suitability for both drinking water and environmentally

- Feature an easy connection with the national electricity grid

- Control pipeline back pressure

- Keep water hammer at an insignificant level, ensuring compatibility with deteriorated pipelines

- Ensure noise levels that are compliant with permitted parameters at the installation site

- Facilitate both mechanical and electrical maintenance

- Be ready to communicate with existing remote-control systems

- Offer a remote management with alarms

- Offer a sufficient IRR for the investment (through medium/high output)

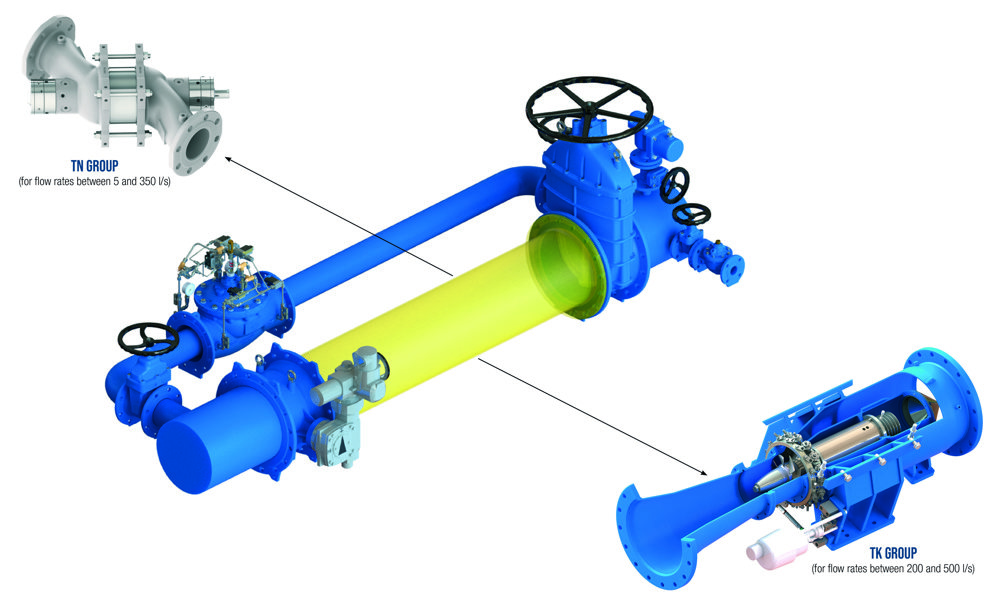

The FR Station normally consists of a line with a fixed production Group “TN” or with a regulating production Group “TK” and a parallel bypass line, including a special control valve for safety operation and flow compensation.

The FR Station is flexible and can be designed in various configurations, with multiple production units in parallel, for high flow rates, or in series, for high pressures.

Particular attention was paid to the “in-line” installation of the production units, which allows their installation on straight sections of pipe, even pre-existing ones.